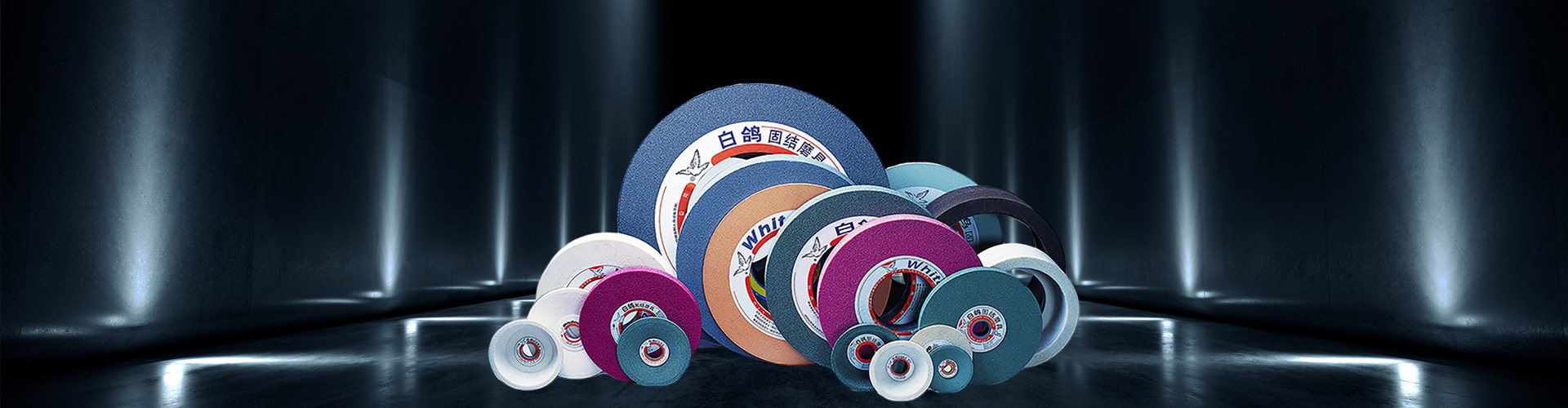

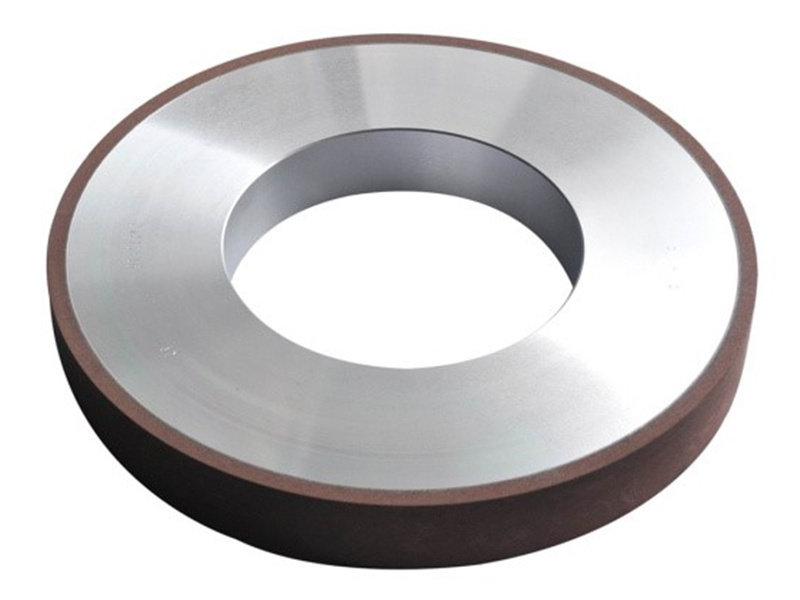

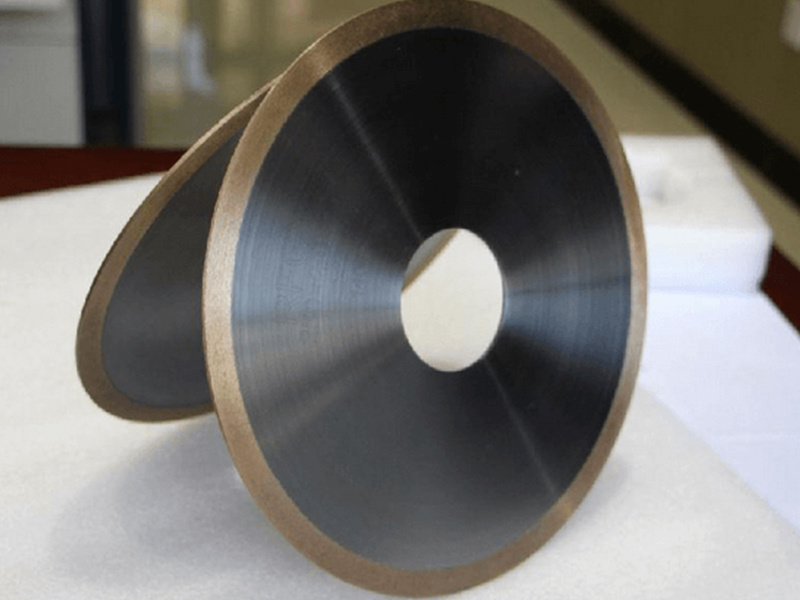

CNC grinding wheels for cutting tools (Special purpose wheels)

Solid carbide, high-speed steel, stainless steel, cermet and other drill bits; milling cutter, reamers and other CNC tools; and various types of blades used in the cutting tool industry.

Keyword:

CNC grinding wheels for cutting tools (Special purpose wheels)

Category:

- Details

-

- Commodity name: CNC grinding wheels for cutting tools (Special purpose wheels)

- Commodity ID: c1-005

Solid carbide, high-speed steel, stainless steel, cermet and other drill bits; milling cutter, reamers and other CNC tools; and various types of blades used in the cutting tool industry.

Industry fields

Cuting tools

Product introduction

The powerful grooving grinding wheel adopts a unique GTM bond formula, which is professionally used for chip flute grinding of carbide milling cutters, drills and other tools with a diameter of Φ6mm or more. High-efficiency, high-precision special grinding tools for various tool and blade processing, supporting various domestic and foreign CNC tool grinders and special grinders for tool and blade processing. The products are mainly used in the grinding of monocrystalline silicon and polycrystalline silicon. Commonly used models are 200*62*80*5*7 and 200*62*80*15*10. Granularity is 100#—1000#. Products can be customized according to customer requirements. We are committed to providing customers with the best solutions, improving customers' processing efficiency and reducing the cost of single-piece grinding.

Performance characteristics

High processing efficiency, good workpiece surface quality, high durability, good shape retention, long service life and high precision. The cutting depth of powerful slotting grinding wheel can reach 5mm at one time, and under this cutting depth, the slotting feed speed of the grinding wheel can reach 50-160mm/min. At the same grinding depth, the feed rate of high temperature resin bonded diamond grinding wheel can only reach 50mm/min at most. When using this grinding wheel for grooving, the workpiece will not have cracks, burns and thermal deformation due to the small grinding resistance and low grinding temperature.

At the same time, due to the small loss of the grinding wheel, it has good surface and edge quality, which prolongs the dressing cycle and service life of the grinding wheel.

Application scope

Solid carbide, high-speed steel, stainless steel, cermet and other drill bits; milling cutter, reamers and other CNC tools; and various types of blades used in the cutting tool industry.

Related download

Related products

Product consultation message