-

White Dove Abrasives Co., Ltd., formerly known as the Second Abrasive Wheel Factory of China, was founded in 1956, and is one of the 156 key construction projects during the First Five-Year Plan period of the country.

-

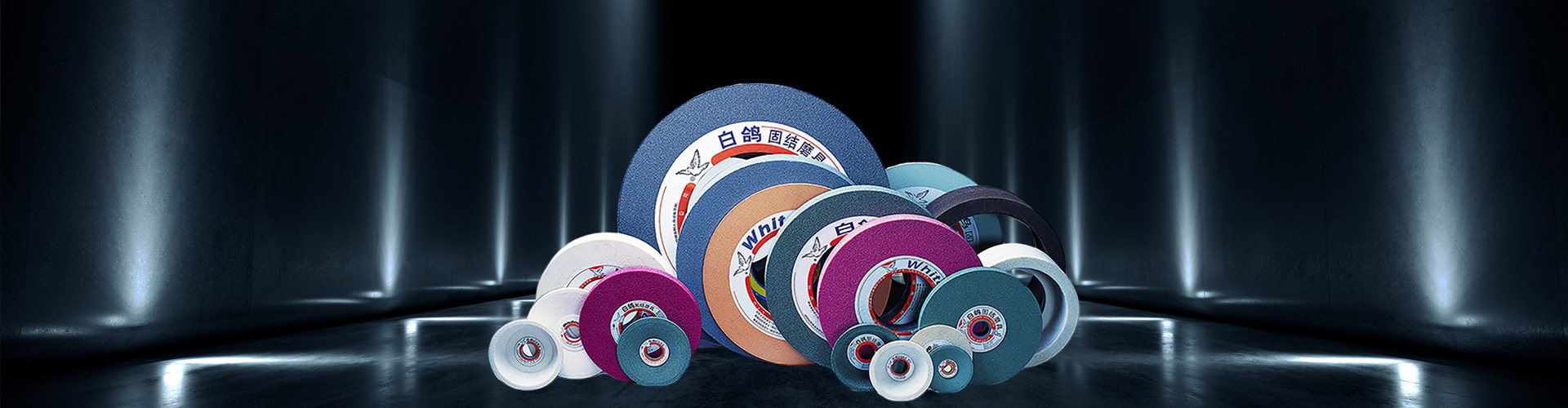

The products are widely used in industries such as automotive, hardware, steel, bearings, metals, wooden board and gear, etc.

-

The main products of WhiteDove include bonded abrasives, coated abrasives, superabrasives and new abrasive materials, covering 8 categories, 17 series and more than 400 varieties, which are widely used in aerospace...

-

White Dove is a national high-tech enterprise with key scientific research platforms such as Henan Engineering Research Center, Henan Engineering Technology Research Center and Henan Postdoctoral Innovation Practice Base...

-

We provide you with the latest corporate news, business development, and industry trends, enabling you to stay informed about the latest trends within WhiteDove.

-

We are delighted to hear your feedback, provide support, or answer any questions you may have. Please feel free to contact us and we look forward to connecting with you and addressing your needs.

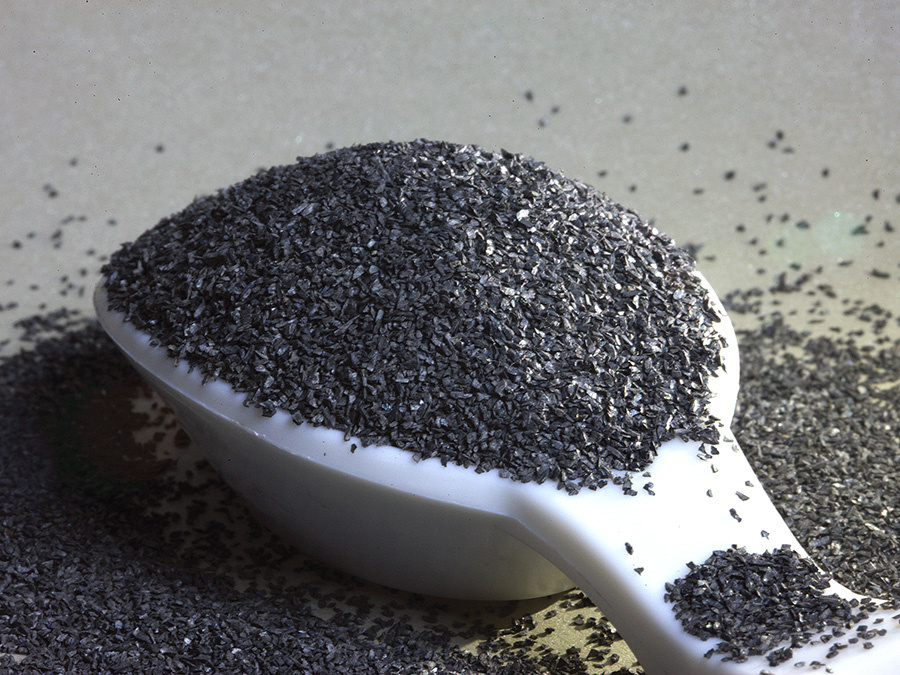

CERAMIC ALUMINA

Ceramic alumina is suitable for grinding alloy steel, hardened steel, tool steel, hard chromium, hard cast iron and other materials.

Keyword:

CERAMIC ALUMINA

Category:

- Details

-

- Commodity name: CERAMIC ALUMINA

- Commodity ID: d-1-007

Ceramic alumina is suitable for grinding alloy steel, hardened steel, tool steel, hard chromium, hard cast iron and other materials.

Product introduction

Ceramic alumina abrasive is a new generation of alumina microcrystalline abrasive produced by sol-gel method. Compared with traditional fused corundum, it has a unique microstructure, high hardness, high toughness, good self-sharpness, fast cutting speed during grinding, most durable grinding life, not easy to burn the workpiece, and low energy consumption. During grinding, each abrasive particle is ground or polished with its crystal micro edge, and its crystal grain is self-sharpened to maintain its sharpness. Ceramic alumina is usually made into coated abrasives (abrasive belt, flap discs, etc.) and bonded abrasives (gear grinding wheel, internal grinding wheel, external grinding wheel, roller grinding wheel, etc.), and the product code is CA.

Performance characteristics

Ceramic alumina has unique microstructure, high hardness, high toughness, good self-sharpness, fast cutting speed during grinding, durable grinding life, not easy to burn the workpiece, and low energy consumption.

Application scope

Ceramic alumina is suitable for grinding alloy steel, hardened steel, tool steel, hard chromium, hard cast iron and other materials.

Related download

Related products

Product consultation message

If you have any needs, please leave your information

Focusing on providing you with abrasive solutions

Address: No. 121 Science Avenue, New Materials Industrial Park, Zhengzhou, China

Postal Code: 450199

Fixed line: +86-371-55983717

Website: www.whitedove.com.cn

Copyright © 2022 White Dove Abrasives Co., Ltd., This website already supports IPV6