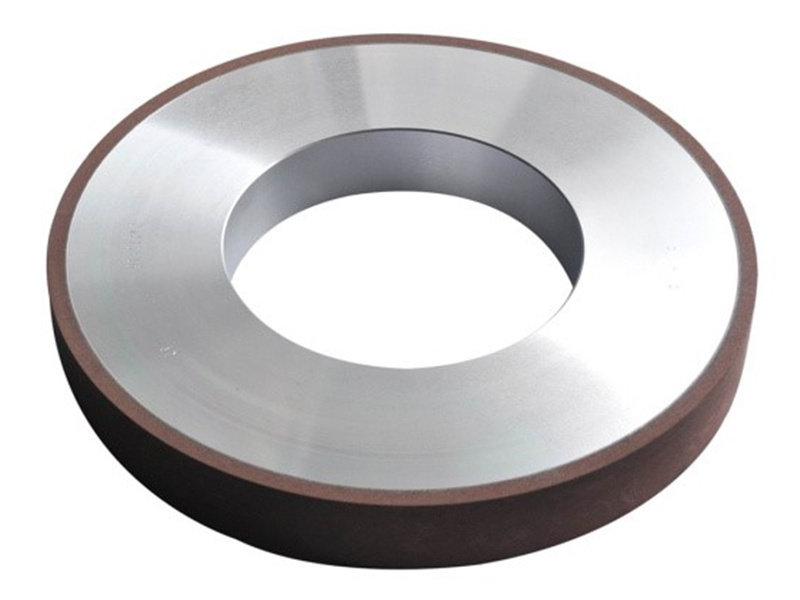

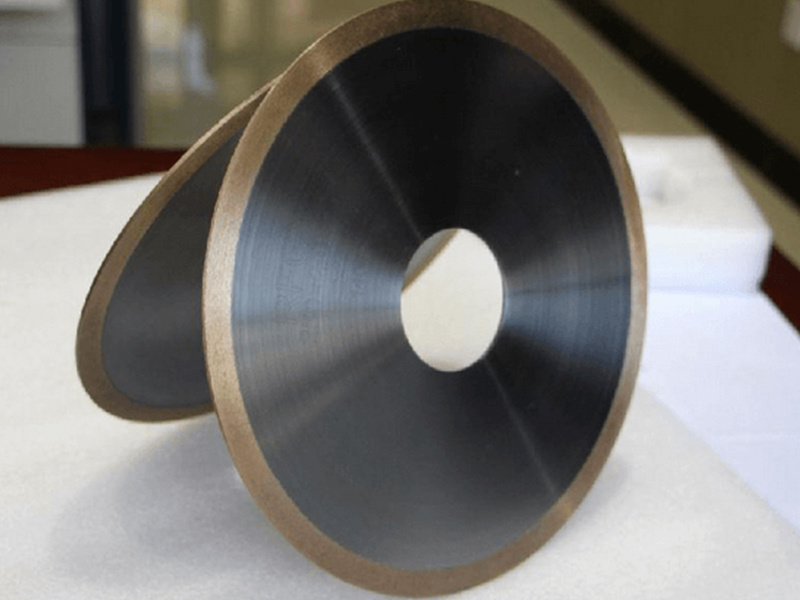

CBN Roll Grinding Wheel (Special purpose wheels)

It is used in the grinding of work rolls, back-up rolls and intermediate rolls of cold-rolled and hot-rolled rolls. The materials of the work rolls in the commonly used cold rolls are 9Cr, 9Cr2, 9Crv, 8CrMoV, etc., and the hardness is HS45~105. The commonly used materials for hot rolls are 55Mn2, 55Cr, 60CrMnMo, 60SiMnMo, etc., with hardness of HB190~270.

Keyword:

CBN Roll Grinding Wheel (Special purpose wheels)

Category:

- Details

-

- Commodity name: CBN Roll Grinding Wheel (Special purpose wheels)

- Commodity ID: c1-006

It is used in the grinding of work rolls, back-up rolls and intermediate rolls of cold-rolled and hot-rolled rolls. The materials of the work rolls in the commonly used cold rolls are 9Cr, 9Cr2, 9Crv, 8CrMoV, etc., and the hardness is HS45~105. The commonly used materials for hot rolls are 55Mn2, 55Cr, 60CrMnMo, 60SiMnMo, etc., with hardness of HB190~270.

Industry fields

Steel

Product introduction

High efficiency, high precision, long life special abrasive tools for roll cylindrical processing. It is equipped with various special grinding machines for rolls at home and abroad to process the outer circle of rolls. In view of the increasing use of high-speed steel (HSS) rolls, ordinary grinding wheels have been difficult to meet the processing requirements, and the CBN grinding wheels that emerged at the historic moment can fully meet the processing requirements. Cooperating with the use of the special grinding machine for roll grinding, under the condition of ensuring the accuracy, the fast and efficient operation of CBN greatly reduces the processing time; the use of the unique integral forming technology on the CBN grinding wheel of the roll grinding solves the problem of poor grinding caused by uneven hardness of the grinding wheel during large grinding amount processing.

Performance characteristics

Sharp grinding wheel, high grinding efficiency, good surface quality of grinding workpiece (no vibration marks, no burns, no scratches), long service life, high durability, high cost performance, and grinding speed can be up to 60-80M/S.

Application scope

It is used in the grinding of work rolls, back-up rolls and intermediate rolls of cold-rolled and hot-rolled rolls. The materials of the work rolls in the commonly used cold rolls are 9Cr, 9Cr2, 9Crv, 8CrMoV, etc., and the hardness is HS45~105.

The commonly used materials for hot rolls are 55Mn2, 55Cr, 60CrMnMo, 60SiMnMo, etc., with hardness of HB190~270.

Related download

Related products

Product consultation message